Surface Grinding for Plastic Parts

Precision Grinding Services for Thermoplastics and Engineered Polymers

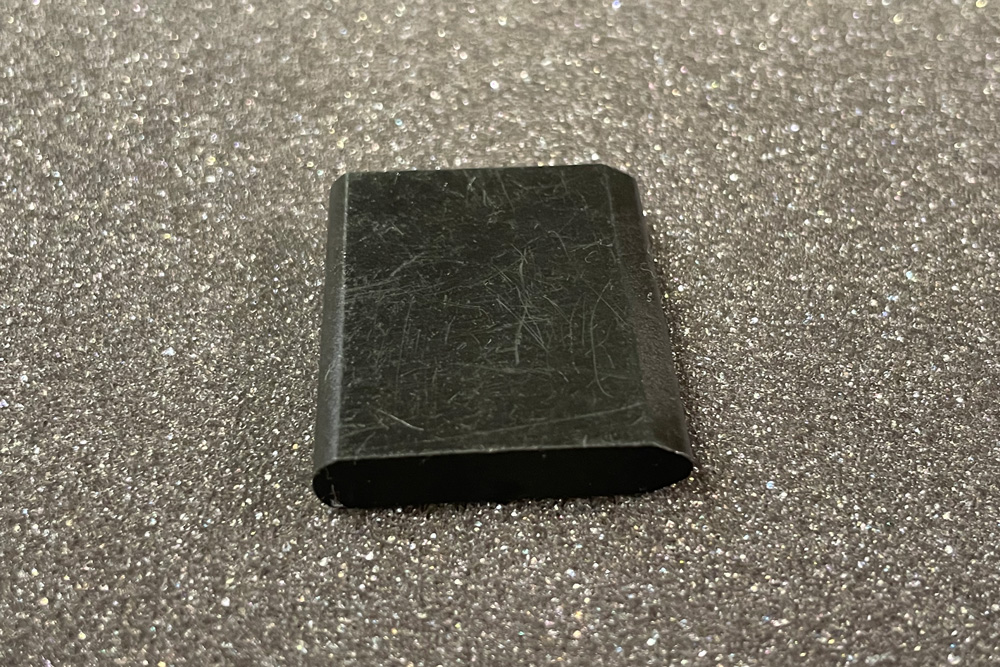

At ASG, we offer specialized surface grinding services for plastic materials, helping manufacturers achieve flat, dimensionally accurate, and clean-finished components made from today’s most advanced polymers. Whether you’re working with UHMW, PTFE, nylon, Delrin (acetal), or other engineered plastics, our team is equipped to meet the unique challenges of grinding non-metallic materials with precision and care.

Why Surface Grind Plastic?

Plastic parts are used across industries like aerospace, medical, electronics, automotive, and industrial equipment, where consistent thickness, flatness, and surface finish are critical.

However, plastic behaves very differently from metal during grinding. It can melt, warp, or become distorted if not processed correctly. That’s why grinding plastic requires not just the right machinery, but also a deep understanding of the material’s physical properties.

At ASG, we use low-friction grinding wheels, controlled feed rates, and precision cooling techniques to prevent heat buildup and material deformation. Our process delivers smooth, burr-free surfaces and ultra-flat finishes ideal for parts that must fit tightly, slide cleanly, or bond properly.

Our Plastic Grinding Capabilities

We work with a variety of plastics, including:

Common Applications

Expertise You Can Count On

With decades of experience, ASG has developed proven grinding techniques that maintain the integrity of even the most heat-sensitive plastics. Whether you need high-tolerance flat parts for technical assemblies or smooth, clean surfaces for cosmetic use, our surface grinding services deliver consistent, repeatable results. Need help with a plastic surface grinding project? Contact us today to request a quote or speak with one of our specialists. We’ll help you turn your plastic parts into precision components.